The X-100 fluxer: What it does

The Katanax X-100 equipment showcases state-of-the-art technology, establishing itself as a premier high-end solution. Its throughput, while optimized for efficiency, aligns with the requirements of lower throughput labs.

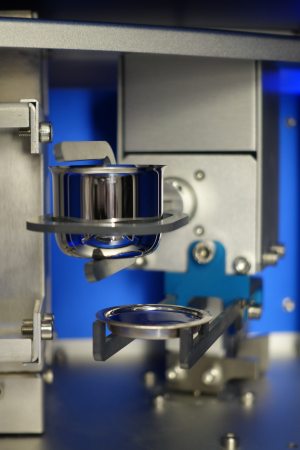

Thanks to a clever electrical and physical design, this compact unit will fit on any counter size and works on both 115 or 230V single phase supply line. The X-100 is equiped with revolutionary heating elements that are resistant to flux and chemical attacks. Heating elements can be changed individually, and will not become brittle. Not only does it features amazing heating elements, but the crucible and mold holders are also made of the same material, allowing a very high life expectation, they can be cleaned and re-used.

The furnace heats up to the required temperature in less than 15 minutes in the morning, and will then remain ready for quick startup of a new sample of XRF bead or ICP solution (with optional solution stirrer module). A PID temperature control ensure temperature stability and it is combined with a unique temperature calibration via molten flux.

The X-100 is pre-loaded with various fusion methods that can be used as is, or can be customized. All fusion methods are protected by a password and can be renamed, deleted or copied, just like computer files and they save automatically. Only the preset methods are protected to avoid accidental overwriting.

Upon turning the instrument on, the furnace door opens, the platinumware holders move forward and out of the furnace, and the door closes.

One crucible is loaded with a few grams of powdered sample, an appropriate flux and often other agents. The crucible is inserted into the crucible holder.

A platinum mold is then installed onto the mold holder, and the safety shield can be closed. Since the platinumware holders are made of ceramics, there is no risk of contamination during the fusion.